PRODUCTS

PRODUCTS

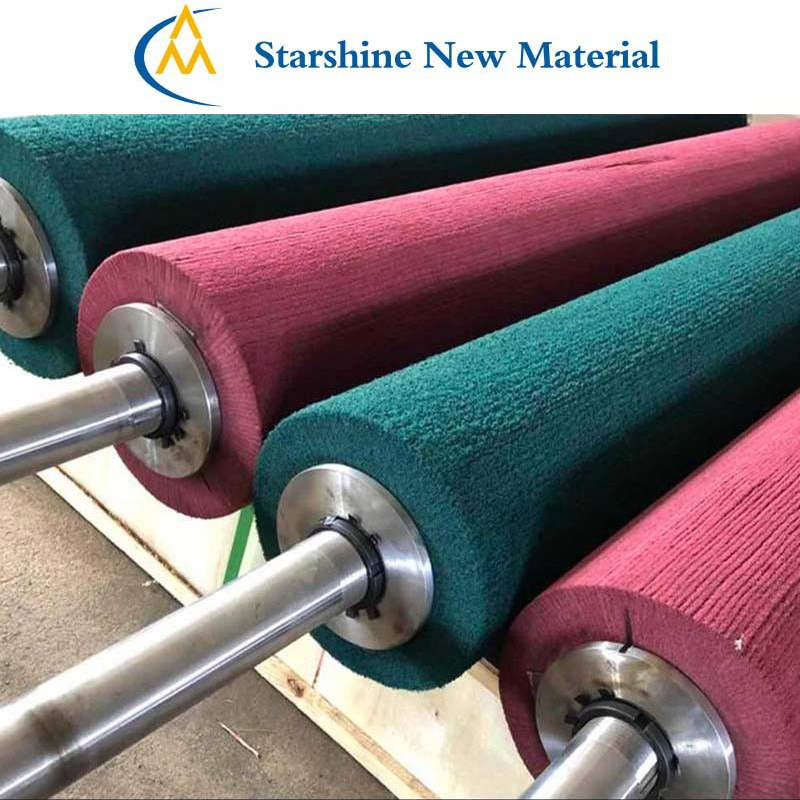

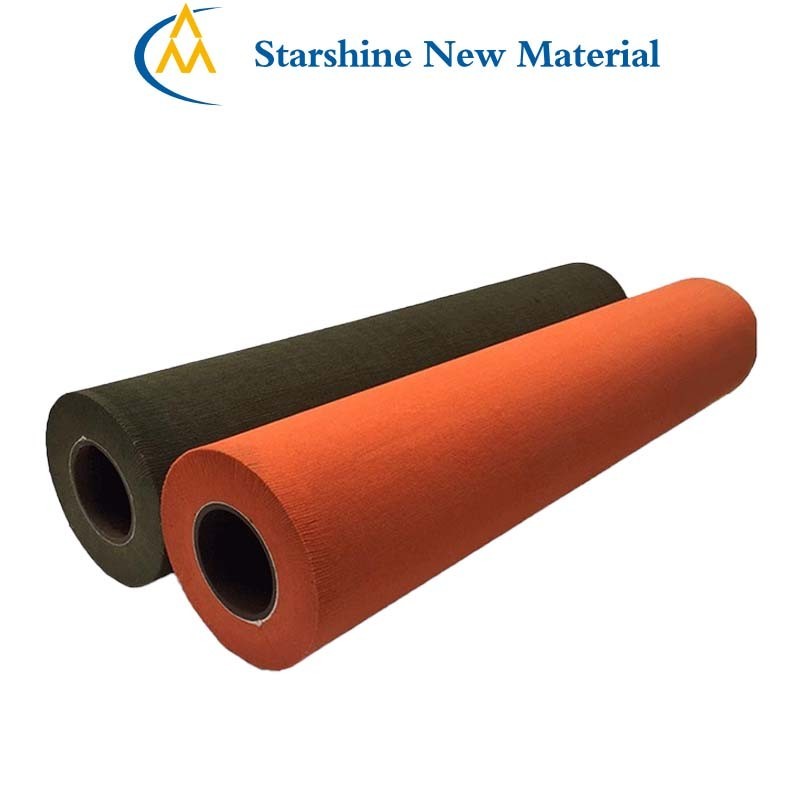

Strip Brush

Introduction and Applications of Strip Brushes

I. Introduction to Strip Brushes

A strip brush is one of the most commonly used types of industrial brushes. Its core structure consists of a long strip-shaped brush body paired with densely arranged bristles. The brush body is typically made of materials such as metals (e.g., stainless steel, aluminum profiles) and plastics (e.g., PA6, PP, PVC). For the bristles, materials like nylon (PA), polypropylene (PP), steel wire, copper wire, and pig bristles can be selected based on specific requirements. The overall form of strip brushes is flexible, allowing customization of length, width, and bristle density.

The core advantage of strip brushes lies in their strong adaptability: they can be cut to size and have their bristle materials replaced according to the application scenario. Additionally, they are easy to install and can be fixed via methods such as card slots, screws, or adhesion, making them widely suitable for various industrial equipment and scenarios.

II. Main Applications of Strip Brushes

Sealing and dust prevention: Used in door and window gaps, equipment guide rails, elevator doors, and other locations to block dust, impurities, rainwater, or odors from entering. They also reduce component friction and extend equipment service life.

Cleaning and impurity removal: Installed on the surfaces of conveyors, assembly lines, machine tools, and other equipment to clean dust, debris, or residual impurities from product surfaces, ensuring processing accuracy or conveyance cleanliness.

Protection and buffering: During the movement of mechanical components (e.g., machine tool guide rails, automated equipment grippers), they provide buffering and anti-scratch effects, avoiding damage to equipment or products caused by hard contact.

Dust removal and airflow guidance: Applied in scenarios such as ventilation ducts, air conditioning outlets, and automobile manufacturing production lines to guide airflow direction while filtering particulate matter in the air, maintaining a clean environment.

Adaptation to special scenarios: Strip brushes can be customized with high-temperature resistant and corrosion-resistant materials for sealing high-temperature furnaces or preventing dust in chemical equipment. They can also be equipped with anti-static bristles to adapt to electronic component production scenarios.

- Commodity name: Strip Brush

- Description

-

Introduction and Applications of Strip Brushes

I. Introduction to Strip Brushes

II. Main Applications of Strip Brushes

Message

Please provide the following valid information, and we will contact you as soon as possible.